It is the day. Today is the day when we finally assemble the first of three motor controllers. Rather than ruin a perfectly well-etched board, we’ll experiment with a vise-mounted, handheld power tool to drill 0.8mm vias into our test board. The test board is a reject from a previous expose-and-etch attempt that had uneven trace widths.

Tag: A3977

Thinking CNC – Before reflow

Haven’t gone out to get an oven toaster yet, so assembly of the first prototype board will have to wait until next weekend. Meanwhile here’s an update of what’s been done so far.

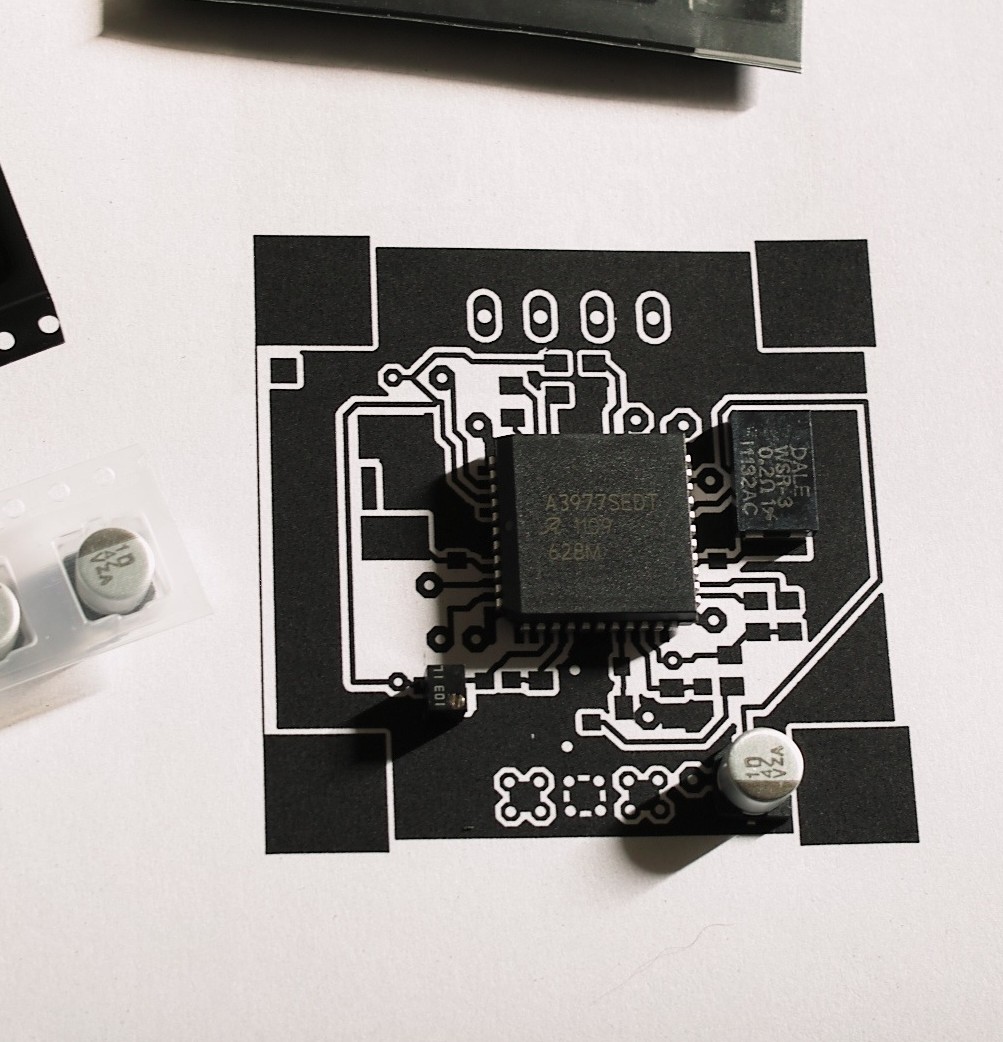

Paper Prototype

Taking a paper prototype to places it really can’t go. This is just a test of placement – the 1-1 size layout simply serves to verify that our parts will rest correctly on the pads.

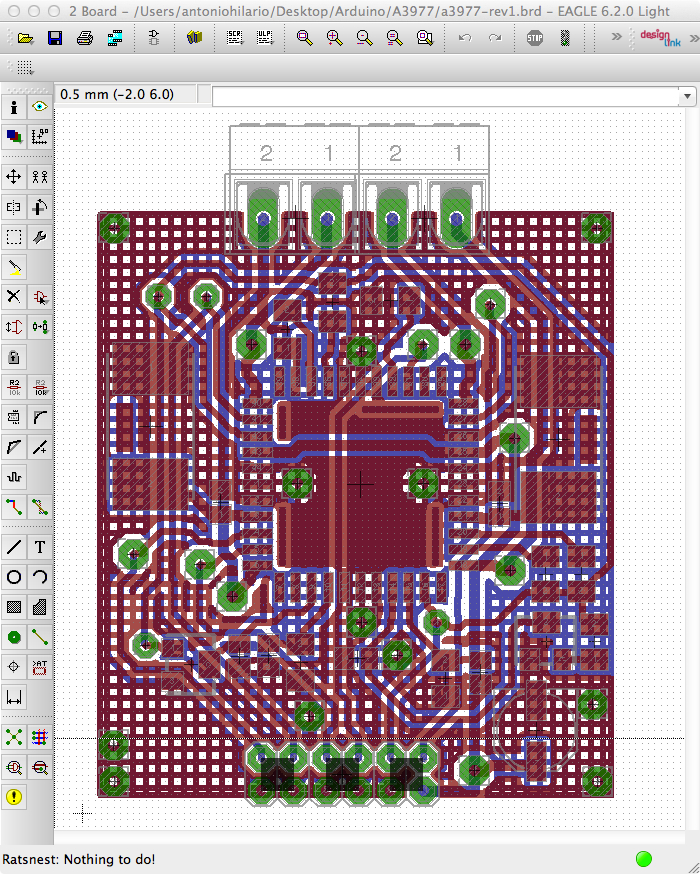

The circuit layout was done in Cadsoft Eagle, with circuit traces that are at minimum 0.5mm wide. It took several days of tweaking the schematic and the layout to ensure that this board could be assembled at all: The screw terminal block (for the motor) and pin headers (for the Arduino) needed to have solder pads all on one side of the board. Any vias would have to be hand-soldered after oven reflow, using snippets of copper wire.

Now to get back to work – etching this over the weekend, after I buy a small oven toaster and thermometer.